FENDER-EDGE

solutions.

testing

FENDER-EDGE

TESTING

Testing is conducted according to “Testing Standard” and “Testing Equipment”. Our laboratory tests every batch of rubber and key materials to ensure compliance with material requirements for each order.

Performance verification tests are typically carried out on-site during manufacture, including: Self-Testing, Authoritative Third-Party Testing, Client-supervised Testing. FENDER-EDGE’s testing equipment and procedures confirm to the most stringent industry standards and calibration requirements stipulated by ISO 17357 standard, PIANC, and OCIMF guidance.

RELATED SOLUTIONS

FENDER-EDGE

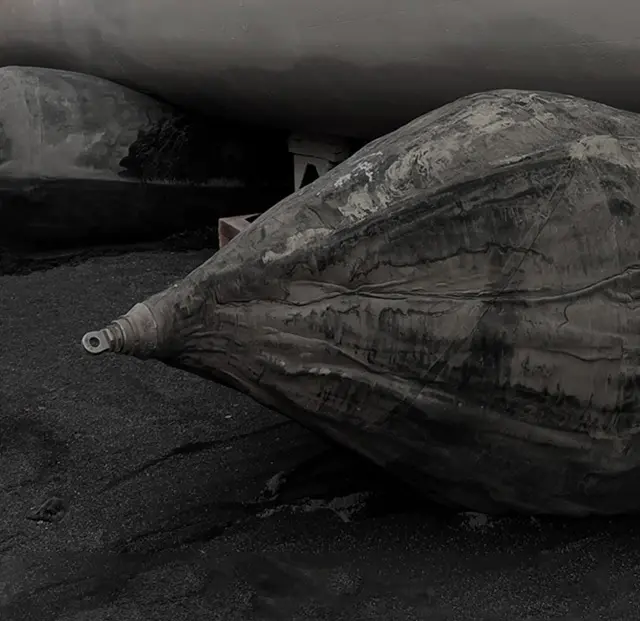

PneumaCell™

ISO 17357-1:2014 just serves as the foundational standard, with its key superiority being the ability to maintain optimal performance especially in various harsh environments.

CushionCell™

Variety of manufacturing method are available to meet different berthing requirements. Low hull pressure, Non-marking, No burst risk, Unsinkable, Anti-UV no discoloration.

Rubber Fender

Rubber fender offer several advantages, including durability, resistance to harsh environmental condition and effective energy absorption to protect vessel during berthing.

ShipGuard™

Safe performance of ship launching airbag is the first priority, nothing else. So all its advantages come only from how to ensure safety. 4.5 times safety factor far ahead in the industry.