FENDER-EDGE

solutions.

DESIGNING

FENDER-EDGE

DESIGNING

The designing provided by FENDER-EDGE come from Fender Raw Materials, Fender Selection and Layout, Special Purpose Fender Design and Customization.

As a crucial system component, the rubber unit’s raw materials, compounding, and mixing process represent a critical and precision-sensitive stage in fender manufacturing.

Calculating the berthing energy of vessels is the first and most important step in the fender design process. FENDER-EDGE technicians support customers during the berthing energy calculation process.

RELATED SOLUTIONS

FENDER-EDGE

PneumaCell™

ISO 17357-1:2014 just serves as the foundational standard, with its key superiority being the ability to maintain optimal performance especially in various harsh environments.

CushionCell™

Variety of manufacturing method are available to meet different berthing requirements. Low hull pressure, Non-marking, No burst risk, Unsinkable, Anti-UV no discoloration.

Rubber Fender

Rubber fender offer several advantages, including durability, resistance to harsh environmental condition and effective energy absorption to protect vessel during berthing.

ShipGuard™

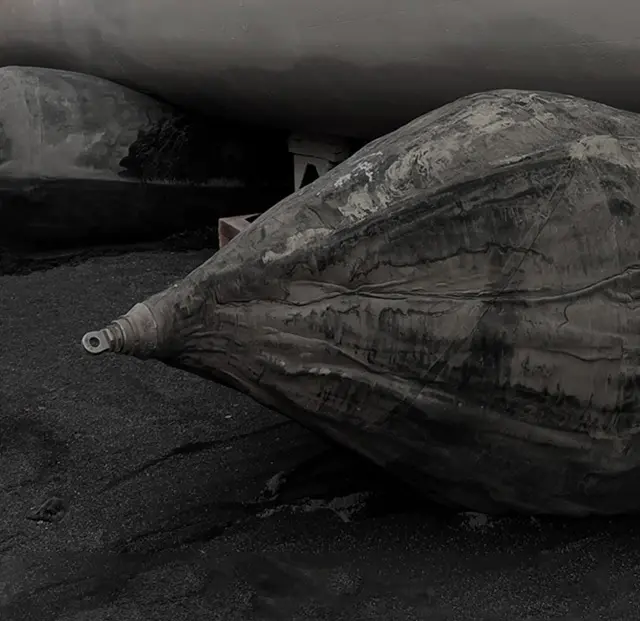

Safe performance of ship launching airbag is the first priority, nothing else. So all its advantages come only from how to ensure safety. 4.5 times safety factor far ahead in the industry.