Total Body Fitness

about us

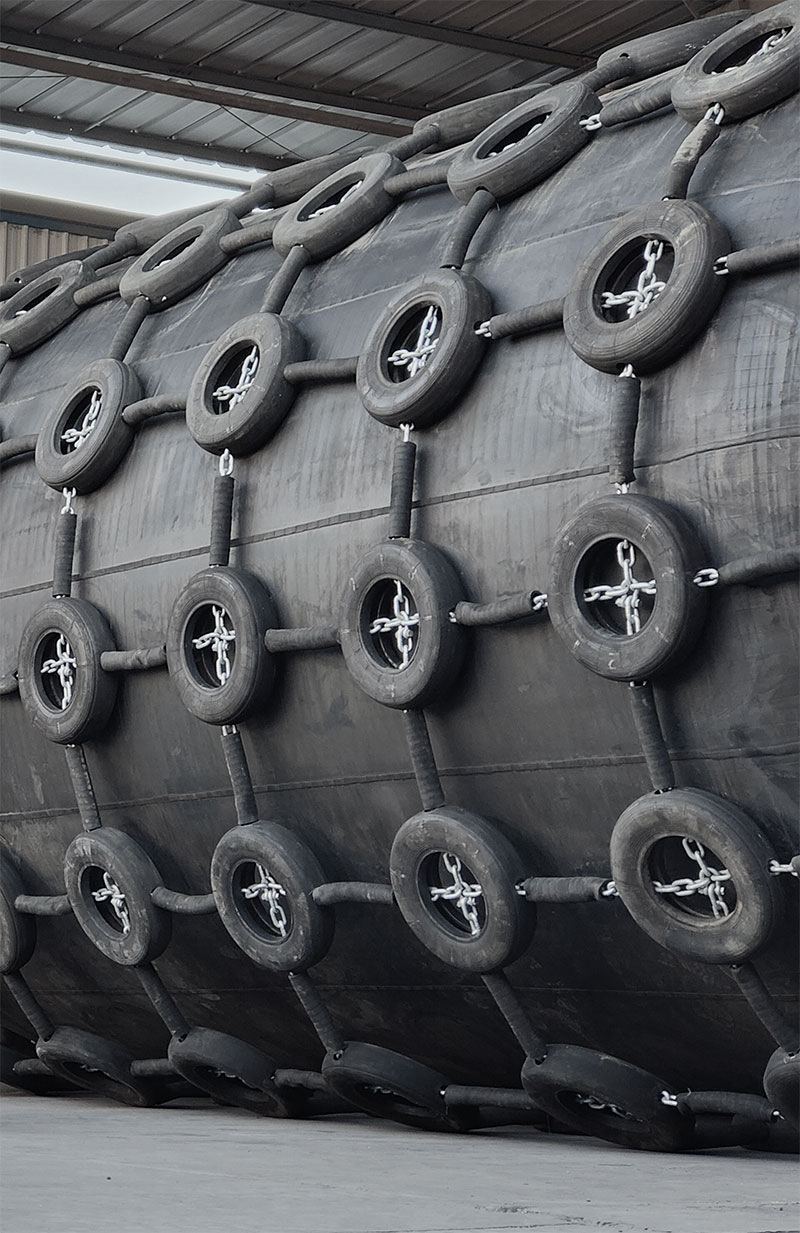

Manufacturing

FENDER-EDGE builds safe and reliable fender systems. We focus on manufacturing all major components in-house at our own facilities. This ensures the highest quality and reliability. The rubber formula and mixing process are critical to fender quality. This includes properties like cold and high-temperature resistance. That's why we give them most important attention. For any part we source, we purchase them only from pre-approved, reputable suppliers. All manufacturing strictly follows FENDER-EDGE's specifications, drawings, calculations, and quality requirements. This guarantees a safe and reliable fender system.

Designing

The designs provided by FENDER-EDGE come from Fender Raw Materials, Fender Selection and Layout, Special Purpose Fender Design and Customization. As a crucial system component, the rubber unit's raw materials, compounding, and mixing process represent a critical and precision-sensitive stage in fender manufacturing. Calculating the berthing energy of vessels is the first and most important step in the fender design process. FENDER-EDGE technicians support customers during the berthing energy calculation process.

Testing

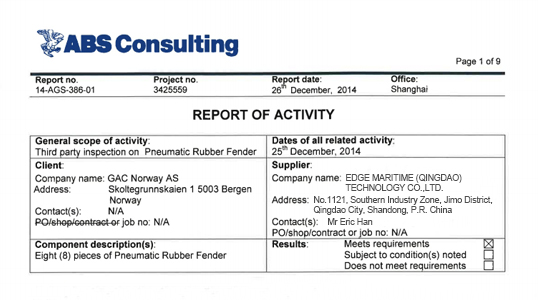

Testing is conducted according to “Testing Standard” and “Testing Equipment”. Our laboratory tests every batch of rubber and key materials to ensure compliance with material requirements for each order. Performance verification tests are typically carried out on-site during manufacture, including: Self-Testing, Authoritative Third-Party Testing, Client-supervised Testing. FENDER-EDGE's testing equipment and procedures conform to the most stringent industry standards and calibration requirements stipulated by ISO 17357, PIANC, and OCIMF.

Innovating

For example, FENDER-EDGE's PneumaCell (Pneumatic Fender). ISO 17357 specifies the requirements for fender structure, pressure, energy absorption, and reaction forces etc. but does not define specific requirements for the Chain Tire Net. Leveraging decades of fender design and application expertise, FENDER-EDGE has conducted comprehensive innovations on the Chain Tire Net to achieve: “Enhanced protection, Superior strength, Extended durability, Operational convenience, Cost-effectiveness".

Technical Supporting

FENDER-EDGE attaches great importance to technical and innovative development. Technical personnel account for 60% of the company's employees, providing sufficient technical support at every stage of the order. “Technical support at an early project stage, Technical support at order stage, Technical support at after-sale”. We partner and clients throughout the entire project lifecycle - from initial technical support to post-delivery assistance. Our dedicated guidance continues until every requirement is met, extending beyond project completion to ensure lasting satisfaction.

Qualifications

Manufacturing qualifications. ISO 17357-1:2014 certification passed by DNV-GL. Authoritative third-party test report by DNV, ABS, BV, CCS, LR. Commercial Certification provided by Chinese official organization “CHINA COUNCIL FOR THE PROMOTION OF INTERNATIONAL TRADE”.

Total Body Fitness

about us

WHO IS "EDGE MARITIME TECHNOLOGY"

EDGE MARITIME TECHNOLOGY core service in marine, infrastructure and facilities, headquartered in China's Eastern Coast. Our approach is rooted in ability to provide clients "INNOVATION", "DESIGN", "SUPERIORITY", "PROJECT EXPERIENCE" in onshore and offshore engineering solutions.

Company technical team account for 60%, we are committed to offer Technical Solutions not Marketing Solutions. "No Edge Defined, All Edge Refined."

WHO IS "FENDER-EDGE"

FENDER-EDGE have nearly 20 years market and technical experience in the exclusive field of marine fender which is truly rare. In the past 20 years, we have seen the integration of marine fender market "Complex, Noisy, Involution, Poor Experience and Even Accidents".

For us, a group of "Dull People" firmly believe that "Product Strength" is the real essence of business. We always keep our enthusiasm and passion for this field and hope to return business to its essence, so we decide to do something, so FENDER-EDGE born out of necessity...

"FENDER"

Specialize in various berth fendering system, ship to ship fendering system as long as 16 years.

"EDGE"

"No Edge Defined, All Edge Refined” is our professionalism..